Beyond using an infrared sensor for precise control of CO2 and separately adjustable chamber, door and perimeter heaters to balance internal temperature, this family can create hypoxic conditions by injecting N2 and directly control humidity to set point by routing air through an evaporator tank. The air pump outside the 165L growth chamber also constantly draws air through a HEPA filter and cycles it back to create ISO Class 5 quality air at positive pressure and minimize contamination. Scientists can choose between a 95C humidified or 145C dry decontamination depending on their laboratory’s procedures. A touch screen makes it easy to enter set points as well as to view or download historical performance. This moderately sized incubator can be stacked and still allow the user easy access to the top chamber.

Features

THE MODERN USER EXPERIENCE YOU EXPECT.

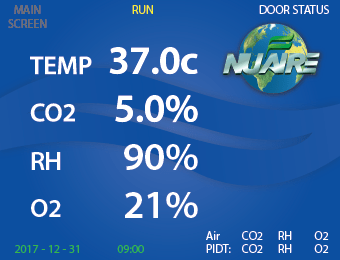

NUTOUCH CONTROL SYSTEM

The NuTouch control system provides you with the user experience you have come to expect from any piece of modern equipment. Change set points, view chamber history, start a decontamination cycle, or perform a calibration procedure from this simple interface. All NuAire CO2 incubators standardize on the NuTouch control system, meaning that once users learn to navigate one incubator they can move seamlessly to any other in the lab.

NUTOUCH CONTROL SYSTEM

THE WARM EMBRACE OF DIRECT HEAT TECHNOLOGY.

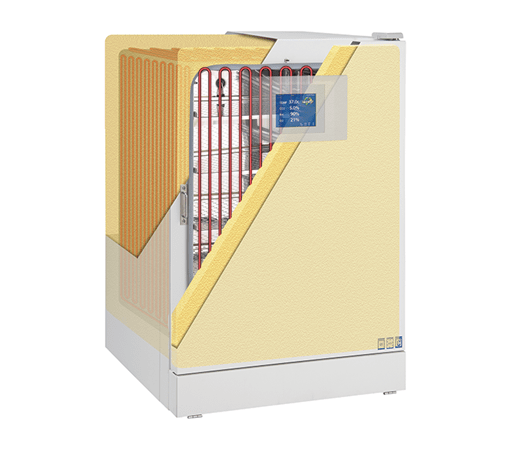

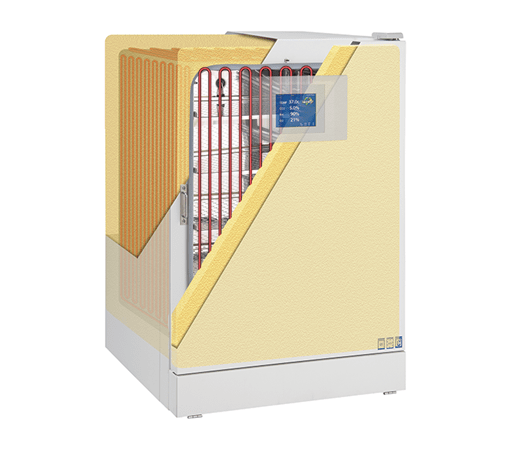

DIRECTLY HEATED CHAMBER

The direct heat incubator uses heating elements placed around the chamber, in the door perimeter, and in the door itself to provide balanced temperature within a steel, insulated chamber environment. Door and perimeter heaters can be adjusted independently to ensure uniformity even when the incubator is installed in more demanding ambient temperatures.

TEMPERATURE UNIFORMITY

CONVENIENT CONTAMINATION CONTROL.

145C HEATED DECONTAMINATION

The direct heat technology enables the use of a 145C decontamination cycle that can be conveniently run overnight in just 8 hours without removing the CO2, temperature, or O2 sensors. The NuTouch control system steps the user through the process with on screen instructions and displays progress throughout each phase of the complete cycle.

CONSTANT CONTAMINATION CONTROL

CELL CULTURES DESERVE THEIR OWN CLEAN ROOM.

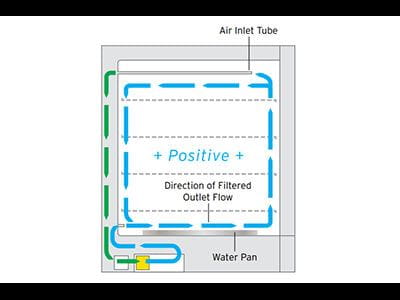

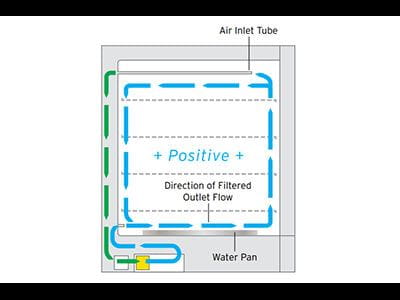

CONSTANT HEPA AIR FILTRATION

Continual HEPA filtration of chamber air complements periodic high heat decontamination to provide Constant Contamination Control. InVitrocell’s design constantly takes a sample of air from the chamber, routes it through a HEPA filter in a compartment outside that inner chamber, and ultimately returns it to create an ISO Class 5 level of clean air in the interior as well as a slight positive pressure. Inside the InVitrocell, your cell cultures are protected by a multi-tiered defense against contamination.

CONSTANT HEPA FILTRATION

CHOOSE THE MODEL WITH THE CAPABILITIES YOUR WORK REQUIRES.

CONTROL OF CHAMBER PARAMETERS

115V/50-60Hz & 230V/50-60Hz (E Suffix)

MODEL

|

TEMPERATURE

|

CO2

|

DECONTAMINATION

|

RELATIVE HUMIDITY

|

O2

|

NU-5700

NU-5700E |

√ |

√ |

|

|

|

NU-5710

NU-5710E |

√ |

√ |

√ |

|

|

NU-5720

NU-5720E |

√ |

√ |

√ |

√ |

|

NU-5731

NU-5731E |

√ |

√ |

√ |

|

√ |

NU-5741

NU-5741E |

√ |

√ |

√ |

√ |

√ |

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM